The seafood industry continually confronts major opportunities and challenges due to its diversity and complexity.

It is one of the largest and most diverse food industries on the globe represented by millions of firms, thousands of species, hundreds of capture and aquaculture production technologies, and thousands of processed products. As the globe’s fastest growing animal protein industry, it represents approximately one-fourth of all animal protein globally. However, although overall demand continues to increase, the seafood industry faces significant challenges including transboundary issues, poor resource management (e.g., IUU — illegal, unreported, unmanaged), environmental impacts (e.g. overfishing, habitat degradation), high product waste, food safety issues, inconsistent product quality, and product mislabeling and fraud that occur at many nodes along the supply chain.

So where to begin? The old saying is the solution to a carpenter involves a hammer.

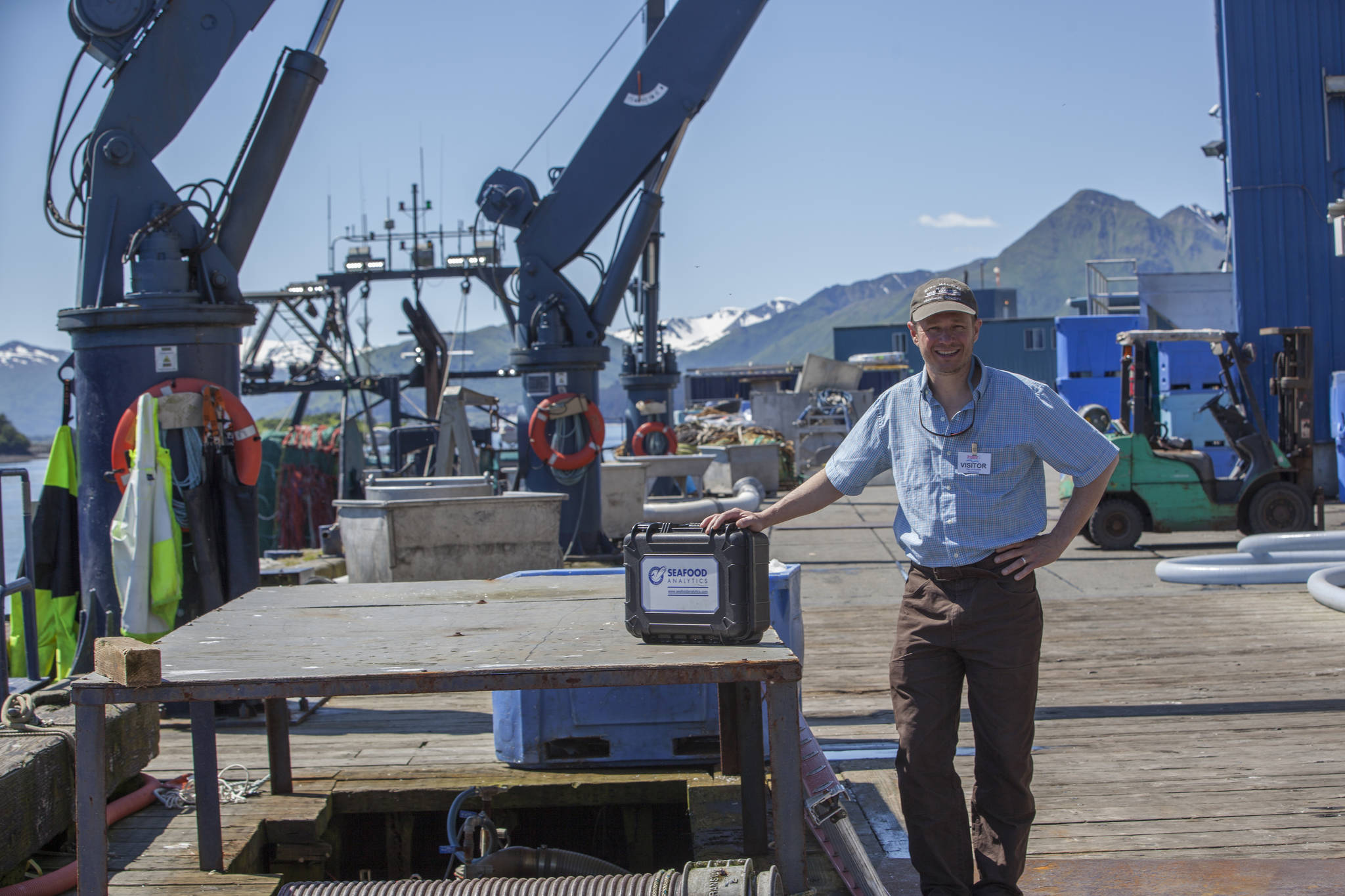

As a fisheries biologist, my focus was always on mapping, charting, evaluating and researching the many facets that can impact the survival and fitness of fish — and not only the harvested economic species such as salmon, but also the less understood smaller forage species that are drivers for healthy ecosystems. Fast forward a few years and I found myself planted firmly in the seafood industry arena holding a new hammer. In this regard, I formed a company called Seafood Analytics that manufactures electronic devices that can measure body composition and degradation/quality of fish.

By simply touching a fish with a handheld unit, many parameters can be predicted on that individual fish including days since harvest, shelf life remaining, and a 100-0 score. I had been using this same technology since graduate school to measure body composition and health of fish, but wanted to see how this technology could be applied to harvested fish, and fish quality post harvest became my world.

So deep down I have been concerned with sustaining fisheries populations and now I was presented with a tool to measure quality electronically. In my seafood quality research, I found that the U.S. Department of Agriculture (USDA) Shrink Report estimates that between 35-45 percent of seafood is thrown away (shrink) prior to consumption. Let me repeat that, 35 percent is thrown away. So what happens when a fillet or fish is thrown away — another replaces it.

Why is shrink so high? It is difficult to assess quality and shelf life within the supply chain. To be safe, some retail marketplaces have a two-day in and out policy – regardless of quality. That is right, after it has been in the retail marketplace for two days, it is thrown away. Add all this up (35 percent of 9.5 billion pounds landed by fishermen in 2015) and it is mind blowing.

How can we reduce shrink and improve sustainability?

No. 1 is improving quality after harvest. The first few hours after harvest are critical to maintain high fish quality. Heat kills quality. For example, leaving a fish for 12 hours at 55 degrees F can triple the rate of degradation when compared to an iced fish. Not just icing fish, but combining proper icing with systems such as pressure bleeding, proper bleeding, slush ice, etc. can improve quality and drastically increase shelf life. No. 2 is utilizing systems within the supply chain that can extend shelf life on seafood products. Examples of this are freezing, ozone, modified atmosphere and expedited shipping. The average shelf life of fresh salmon (depending on who you talk to also) is 16-22 days, the average shelf life of frozen salmon is about one year. Theoretically, if industry was entirely frozen product, what would shrink at retail look like? What would the existing fishing industry look like? Maybe a shift from quantity to quality would ensue.

The industry as a whole is capable of adopting scalable and modular tools to improve the quality and profitability of seafood while reducing waste. Building on the success of economically viable processes that are modular and scalable is the next step. New and scalable technologies make these next steps possible for small and larger entities along the entire supply chain that can maximize quality, profitability, and sustainability of marine resources.

I don’t believe that any one single “hammer” is the answer to sustaining marine resources, but combining all the tools to build a sustainable approach to marine resources will provide the foundation to build a home that we all can live in.

• Dr. Keith Cox is part-time faculty at the University of Alaska Southeast and lives in Juneau. He is also a co-founder of Seafood Analytics. The thoughts and words here have also stemmed from collaborative work with Kirk Hardcastle (Taku River Reds) and Gil Silvia (Director, Coastal Oregon Marine Experiment Station, Oregon State University). “Sustainable Alaska” is a monthly column, appearing on the first Friday of every month. It’s written by UAS Sustainability Committee members who wanted to promote sustainability. The views expressed here do not necessarily represent the views of the University of Alaska Southeast.